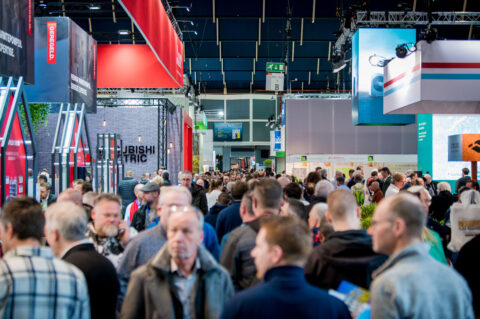

By using robots, companies can establish a flexible and scalable logistics operation in which fewer people do more work. The interest in robotisation is enormous, which is why the ICT & Logistiek and Logistica Next trade fairs from Tuesday 8 to Thursday 10 November will be dominated by robot projects. The Royal Dutch Jaarbeurs will feature dozens of exhibitors offering a complete overview of the possibilities robots offer in the workplace. In addition, leading speakers from theory and practice will be on hand to give visitors insights into robotisation and automation.

Corien den Ouden, exhibition manager: "The unpredictability and uncertainty in logistics is greater than ever, while it remains extremely difficult to find good staff. No wonder many companies are looking at the potential of robots to meet growing customer expectations. Robots are generally quick to deploy and do not require large and lengthy conversions of existing warehouses. Additional advantage: investments are relatively low compared to traditional forms of automation."

Robots prevent staff from travelling miles in warehouse

Autonomous mobile robots (AMRs) are particularly popular. They provide support for order picking, transporting and sorting products and prevent employees from having to travel kilometres a day along the racks in the warehouse. At ICT & Logistiek and Logistica Next, several AMR suppliers will be present, from Lowpad from the Netherlands to foreign specialists such as Caja Robotics, Hai Robotics and Addverb Technologies. One notable name is France's Exotec with a solution that most closely resembles a cross between an AMR and shuttle system.

Besides AMRs, industrial robots and collaborative robots are also popular for a variety of processes, such as stacking goods or picking items from bins. Gibas and Smart Robotics are specialists in this field, while traditional warehouse fitters are also increasingly integrating robots into their automated storage and order picking systems.

What remains human work?

At the trade fairs, experts share their experiences with automation and mechanisation. For example, Wouter Sluiter of Fonq and Roel Megens of Sligro talk about what remains human work. Prof René de Koster of Erasmus University Rotterdam explains how new forms of automation and robotisation can be used to improve performance on the warehouse floor. He shows new concepts that would not be possible without these innovations. Experts from automation specialists such as TGW, Kardex, Vanderlande, Vanas, Exotec and Addverb Technologies will also share their insights.